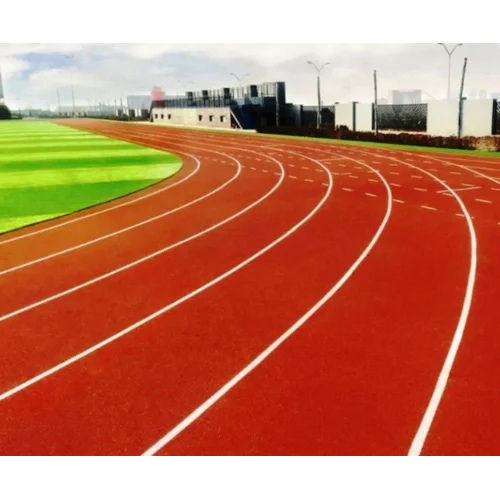

Sandwich Running Track Flooring

Product Details:

Sandwich Running Track Flooring Price And Quantity

- 1000 Square Foot

- 250.0 INR/Square Foot

Sandwich Running Track Flooring Trade Information

- 5000

- 10 Days

- No

- BAGS

- I i a ' ] [ ' A l l n d

- ISO,NBE, ITF CERTIFIED

Product Description

|

Material |

Epdm |

|

Usage/Application |

Running |

|

Court Type |

Outdoor |

|

Floor Type |

Sandwich |

|

Color |

Red |

|

Finish |

Matte |

|

Payment Mode |

Online and Offline |

|

Service Duration |

10 Days |

|

Service Location |

Ahmadabad |

|

Service Mode |

Offline |

This is for informational purposes only. For medical advice or diagnosis, consult a professional.

Sandwich running track flooring is a popular choice for athletic facilities seeking a balance of performance, durability, and cost-effectiveness. It combines elements of both porous and full PUR (Polyurethane) track systems.

Key Components and Construction

A sandwich running track typically consists of the following layers:

- Sub-base: A compacted layer of aggregate or asphalt providing a stable foundation.

- Primer: Applied to the sub-base to improve adhesion of subsequent layers.

- Base Layer: A resilient layer made of SBR (Styrene-Butadiene Rubber) granules bound with polyurethane, providing shock absorption.

- Top Layer: A wear-resistant layer made of EPDM (Ethylene Propylene Diene Monomer) rubber granules embedded in a polyurethane coating, providing durability, grip, and weather resistance.

Key Properties

- Shock Absorption: Provides good shock absorption, reducing impact on joints and muscles.

- Durability: Withstands heavy use, UV radiation, and varying weather conditions.

- Spike Resistance: Resists damage from running spikes.

- Weather Resistance: Can be used in all weather conditions.

- Cost-Effective: Offers a good balance of performance and cost compared to full PUR systems.

Applications

Sandwich running track flooring is commonly used in:

- School and university tracks: For physical education and athletic programs.

- Community and recreational tracks: For general fitness and training.

- Training facilities: For athletes to train and improve their performance.

Advantages

- Good Performance: Provides a suitable surface for running and athletic activities.

- Injury Prevention: Reduces the risk of injuries due to its shock-absorbing properties.

- Durable: Can withstand heavy use and varying weather conditions.

- Cost-Effective: Offers a good balance of performance and cost.

- Weatherproof: Can be used in all weather conditions.

Disadvantages

- Not as High-Performance as Full PUR: Does not offer the same level of elasticity and energy return as full PUR systems.

- Installation: Requires specialized equipment and expertise for proper installation.

International Standards

While not always meeting the most stringent requirements for international competitions, sandwich systems can be certified by organizations like World Athletics for certain levels of competition.

Maintenance

Regular maintenance is essential to prolong the life and performance of sandwich running track flooring. This includes:

- Regular cleaning: To remove dirt, debris, and contaminants.

- Periodic inspections: To identify and repair any damage.

- Occasional resurfacing: To restore the surface's performance characteristics.

Overall, sandwich running track flooring is a versatile and cost-effective option for athletic facilities seeking a balance of performance, durability, and budget. It provides a suitable surface for a wide range of athletic activities and training.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sport Flooring Service' category

|

PUJAN CONSTRUCTION (OPC) PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese